Rope Construction

3 Strand

The use of 3 strand ropes dates back to prehistoric times. Traditionally, natural fibers were used to make the first three strand ropes. Twisted ropes are built by first twisting multiple fibers together (synthetic or natural fiber) and forming a single strand. From that point three strands are laid together to create a three strand rope. This is the most common rope construction for general purpose use.

Hollow Braid Rope

Hollow Braid ropes are produced in 8 &16 strand (carrier) constructions with a hollow core. Most common rope is a hollow braid polypropylene that is manufactured in a variety of colors. One of its best characteristics is its ability to be easily spliced. An economical general purpose rope.

Double Braid

Double braided ropes known also as braid on braid are manufactured by first manufacturing a braided inner core and then covering the core with a braided jacket. The braided inner core can consist of many types of synthetic fibers that will determine strength, elongation, and other critical requirements a specific application may demand.

Diamond Braid

Diamond Braid ropes are produced in 8 or 16 strand (carrier) constructions. Diamond braid ropes have a diamond pattern on the outside cover of the cord. The construction allows for a fiber core that can be used to control elongation, strength, or other critical requirements needed.

Solid Braid

Solid Braid ropes are produced in 12 and 20 strand (carrier) constructions. The construction of the rope creates a firm round rope that maintains its shape while in use, yet flexible. Solid braided ropes performs well on blocks and pulleys. A variety of fibers can be used based on the required application. Multiple color combinations are also possible with this rope construction.

Shock Cord

Shock Cord (Bungee Cord) is produced on a 16 strand (carrier) braiding machine. The braided outer cover can be made of nylon, polyester, cotton, or multifilament polypropylene yarns. The core is made up of multiple strands of silicone rubber. Based on the rubber used in the core, typical elongations can run 120-140%.

12 Strand

12 Strand Single braids are manufactured by twisting synthetic fibers into a single strand and then winding the fiber on to braider bobbins to create a single strand. From there the bobbins are put on to a 12 strand braiding machine to make the finished product. 12 Strand ropes provide a torque free, non hockling rope that is easily spliced in the field reducing down time.

Woven Products

Weaving is a method of textile production in which sets of fiber are interlaced to form a flat tape or webbing. Tapes can be produced from a variety of fibers depending on the application requirements. Continuous feed fiber capabilities allow for a splice free continuous length package of up to 100,000 ft. Tape can be sequentially footage marked and lubricated to reduce friction.

Twine Products

Twine is a light weight string composed of natural or synthetic fibers twisted together. Cotton tying twines, agricultural synthetic bailer and binder twines, and synthetic tying twines are the most common twines found in the market today.

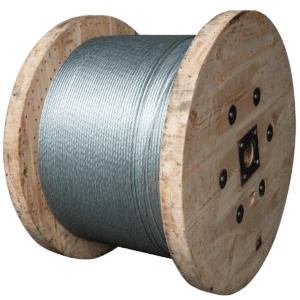

Cable and Wire Products

Cable and wire rope products are available in a variety of constructions, sizes, and finishes. These versatile products are commonly used to lift, hoist, separate, secure, repair, support, and brace items safely and effectively.

Custom Made Products

Erin Rope Corporation is a domestic rope manufacturer located in Blue Island, IL, just south of Chicago. Its braiding equipment, the most modern in the cordage industry, is exclusively high speed, state of the art, German equipment that allows for efficient manufacturing of high quality products. While we already manufacture a wide range of standard and custom products, let us know what your rope requirements are and we will work with you to engineer a product that meets your needs.