What Is UHMWPE Rope?

UHMWPE Rope: High-Performance Pulling Rope

In utility and industrial pulling applications, not all rope materials are created equal. When strength, control, and consistency under load are non-negotiable, UHMWPE rope, short for Ultra-High Molecular Weight Polyethylene, has become the new standard for high-performance synthetic pulling lines.

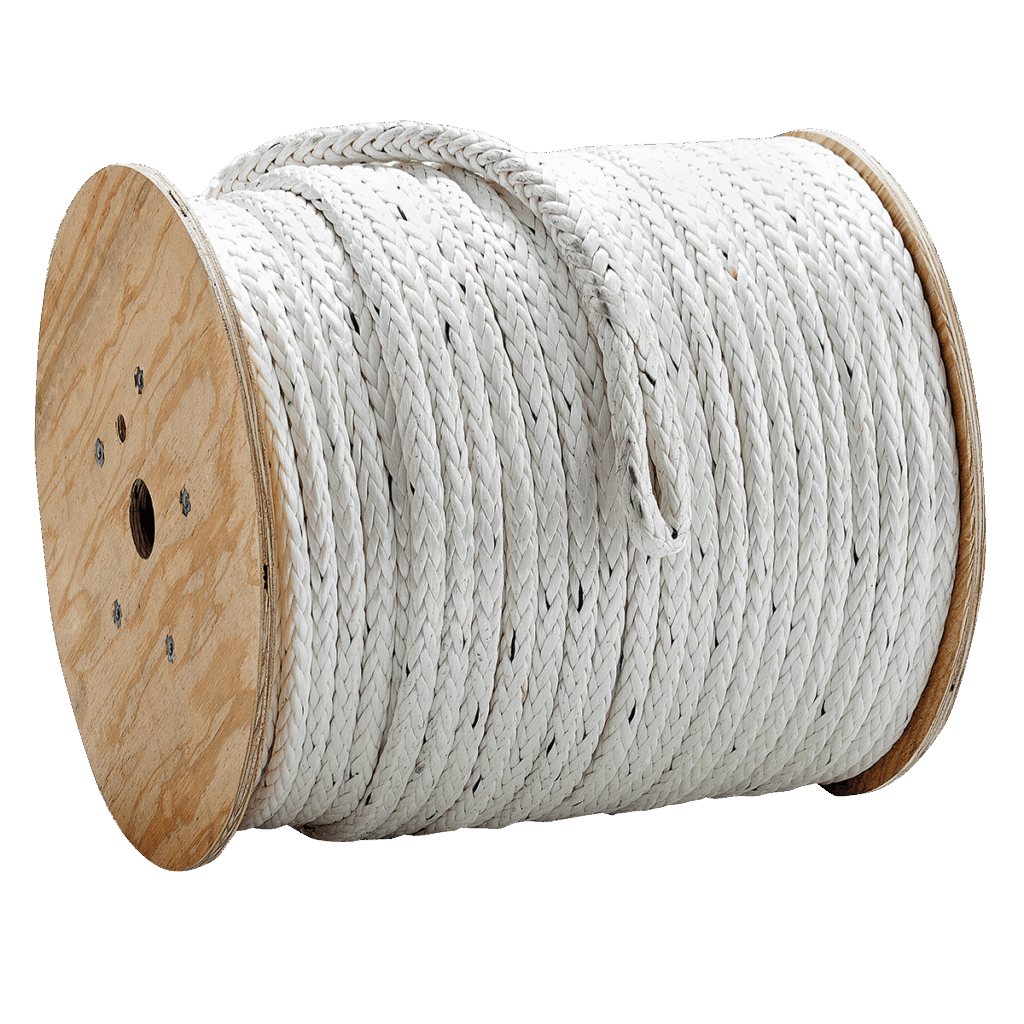

At Erin Rope Corporation, our E/R 12 Slick Rope is the next generation of pulling technology. Manufactured from premium UHMWPE fiber, it delivers exceptional tensile strength, minimal stretch, and zero water absorption, all in a rope that’s lighter, easier to handle, and more durable than conventional polyester or polypropylene lines.

In the sections below, we’ll examine how UHMWPE rope is constructed, why its performance characteristics matter, and the types of applications it excels in.

What Is UHMWPE and What Sets It Apart

UHMWPE (Ultra-High Molecular Weight Polyethylene) is an advanced thermoplastic known for its long molecular chains and exceptional load-bearing properties. These fibers have a molecular weight more than 10 times that of standard polyethylene, giving them a combination of strength and low friction unmatched by most synthetic materials.

When engineered into rope, UHMWPE offers a strength-to-weight ratio up to five times that of steel wire and far superior to that of conventional pulling lines. The result is a rope that delivers maximum pulling capacity without the bulk, stretch, or fatigue that can slow down demanding installations.

Inside Erin Rope’s E/R 12 Slick Rope

Our E/R 12 Slick Rope is made from 12 strands of high-strength UHMWPE synthetic fiber, precision-braided for uniform, torque-free construction. This design ensures high load efficiency, smooth handling, and durability under repeated use.

Key performance highlights include:

- High-strength 12-strand synthetic fiber rope

- 5× stronger than conventional pulling ropes

- Low stretch and low creep for controlled pulls

- 25% reduction in coefficient of friction, minimizing heat and resistance during conduit pulls

- 0% water absorption, maintaining full performance in any environment

- Spliced pulling eyes for fast, reliable attachment

These attributes make the E/R 12 an ideal solution for professional overhead and underground cable-pulling operations where reliability, safety, and cost efficiency are paramount.

Performance Characteristics: What You Should Expect

For decision-makers evaluating rope materials, UHMWPE delivers several standout performance traits:

- Strength-to-weight ratio: Because of its molecular structure, UHMWPE rope carries loads commensurate with heavy steel wire rope while weighing a fraction of the mass.

- Low stretch and creep: In critical lifting, rigging, or pulling applications, elongation under load needs to be controlled. UHMWPE fibers offer very low elongation and minimal creep compared to natural fibers or many standard synthetic fibers.

- Durability in demanding environments: UHMWPE rope resists water absorption, so it maintains strength even in wet conditions. It also tolerates oils, most acids/alkalis, and has strong abrasion resistance.

- Lightweight handling: The low density of UHMWPE makes the rope easier to deploy, retrieve, and store, which is essential in operations where handling time, transport weight, or operator fatigue are key factors.

Applications: Built for High-Demand Cable Pulling

Our E/R 12 Slick Rope is designed specifically for overhead and underground cable-pulling applications, where precision, repeat use, and safety are key. It’s trusted across:

- Electrical utility installations

- Telecommunications

- Substation and transmission work

- Power distribution networks

- Infrastructure and renewable energy construction

Its low friction and high strength make it especially effective for long conduit runs and heavy cable bundles. At the same time, its synthetic construction provides the flexibility needed for repeated job-site deployment.

Available Sizes and Cost-Effective Performance

Erin Rope’s UHMWPE rope is available in a range of diameters and lengths to meet specific job requirements. Whether your team needs a shorter spool for controlled installations or extended lengths for long conduit runs, each configuration maintains the same precision construction and verified tensile strength.

Because UHMWPE offers such a high strength-to-weight ratio, users gain long-term cost efficiency through fewer replacements, less downtime, and reduced handling effort. It’s a rope designed to work hard, last longer, and lower total job cost over its service life.

Why UHMWPE Rope Is the Industry Benchmark

Beyond raw strength, UHMWPE rope provides a safer, more consistent pulling experience. Its predictable elongation and reduced friction translate to smoother cable movement, less wear on conduit, and lower mechanical strain on winches and pulling heads. It also eliminates the water absorption and stiffness problems that can degrade polyester and nylon lines in humid environments.

Every E/R 12 Slick Rope is manufactured to meet rigorous quality standards and tested to verify tensile strength, elongation, and performance. Our commitment to quality ensures that each spool delivers the consistency professionals expect on critical pulls.

For utility contractors, electrical professionals, and industrial crews who demand precision, strength, and long-term dependability, UHMWPE isn’t just an upgrade; it’s the standard for modern performance.