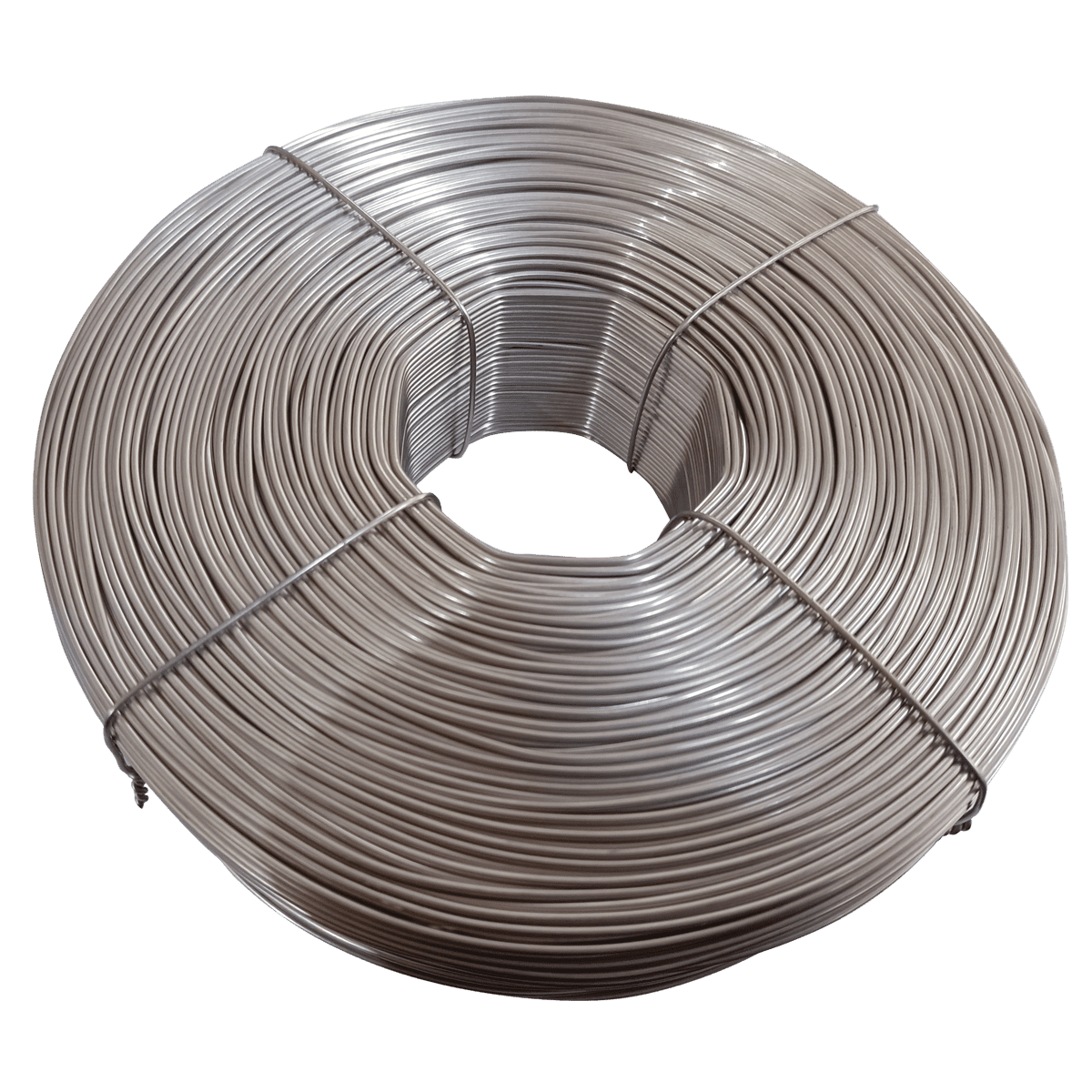

Stainless Steel Lashing Wire

Highlights

- Made from 302 and 403 stainless steel alloys

- Magnetic thermally non-hardening ferritic stainless steel

- Ideal for securing aerial cables to support structures

- Annealed for flexibility and uniform, fine-grain structure

- High corrosion resistance

- Available in multiple coil lengths, including 1200’ and 1600’

Description

Stainless Steel Lashing Wire is a durable solution for securing aerial cables, such as telecommunications and fiber optic lines, to support structures. Available in two types—302 and 430 stainless steel—this lashing wire meets various environmental and industrial needs. Type 430 is excellent for general use, while Type 302 provides greater corrosion resistance for industrial environments.

Each wire is annealed for a uniform grain structure that enhances its flexibility and ease of handling. This wire can handle heavy loads with tensile strengths between 95,000 and 125,000 PSI (depending on the type).

It is available in coil lengths of 1200' or 1600' and is designed for use with popular lashing tools like the C or J2 lasher.

Click button to download the cut sheet automatically