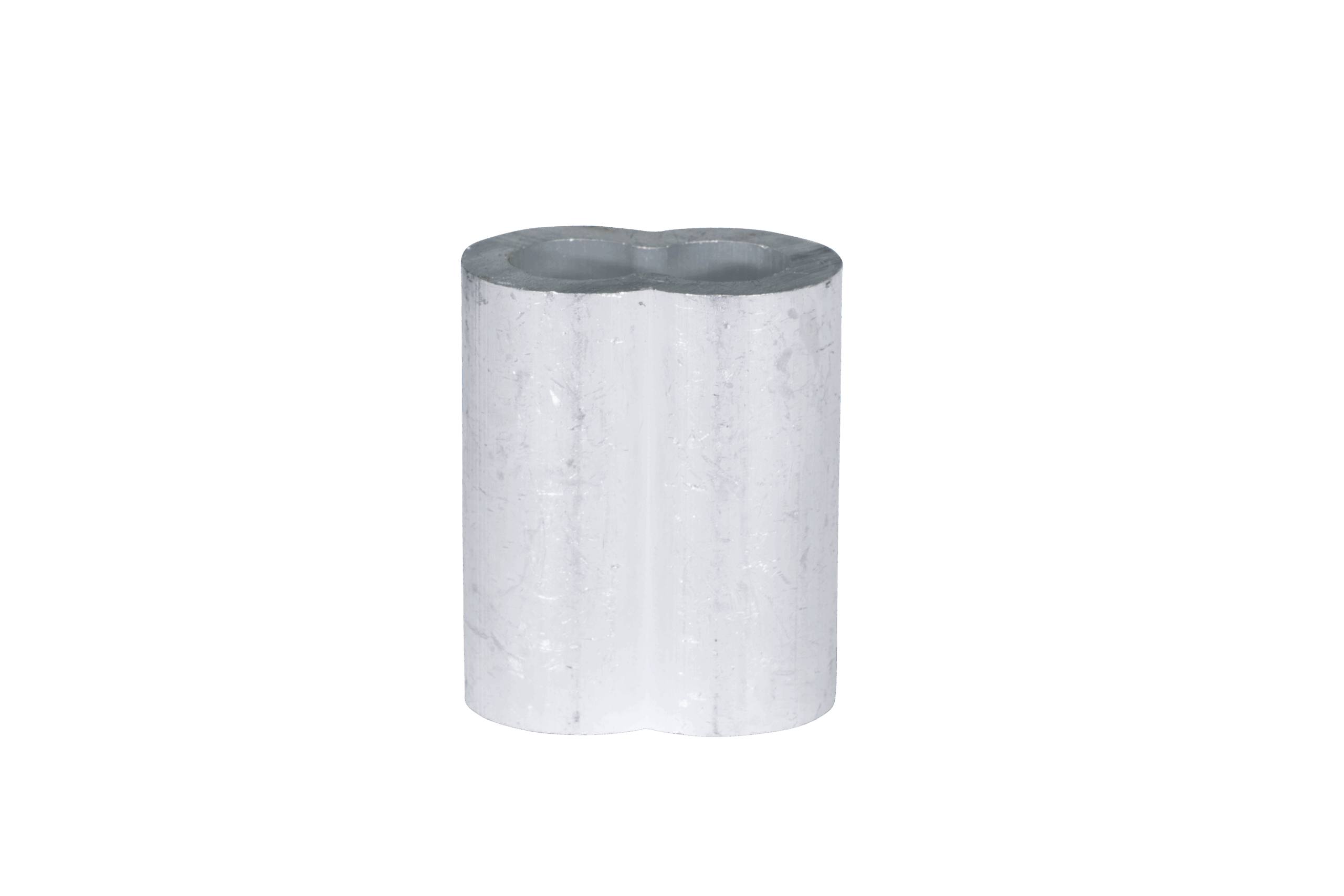

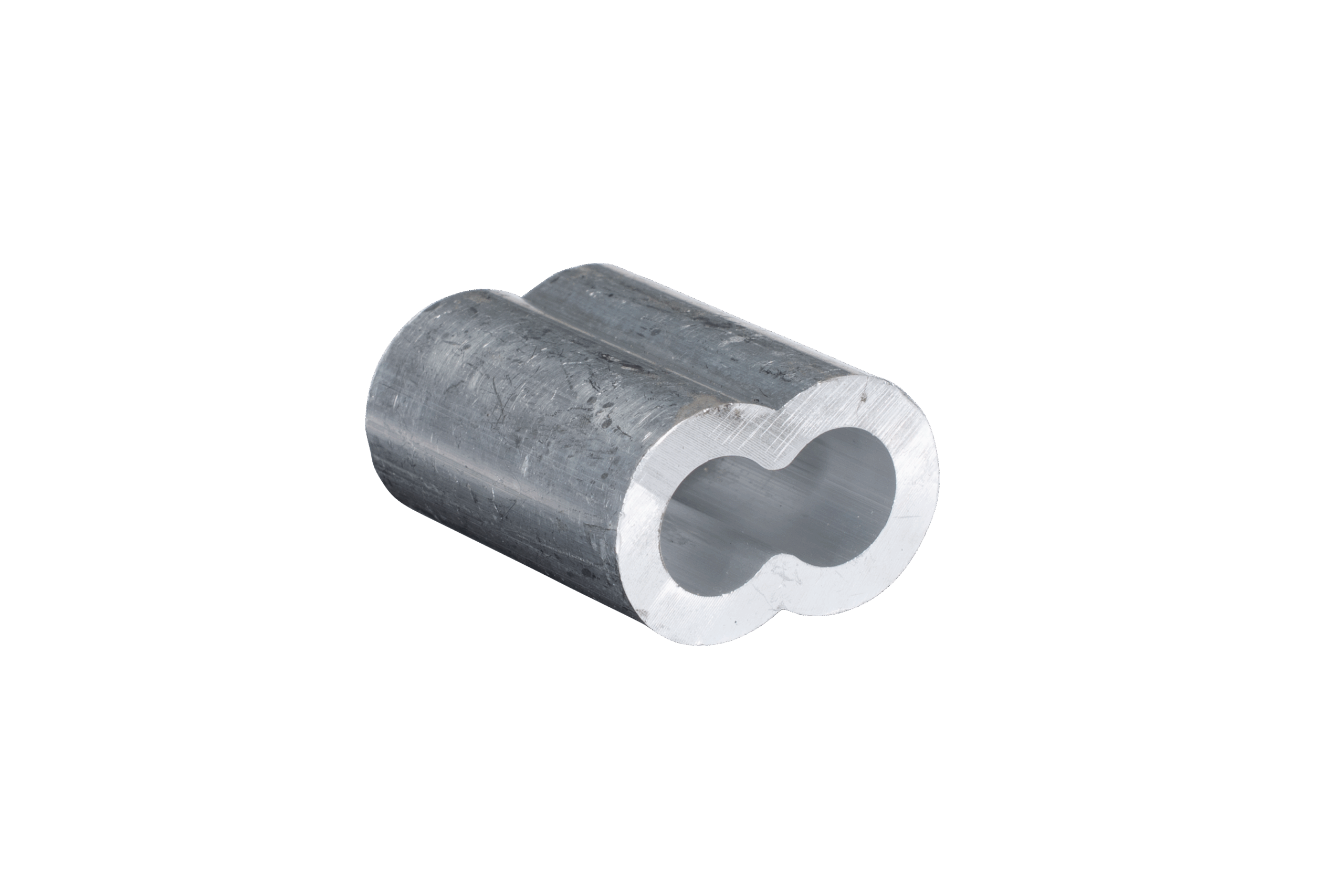

Aluminum Cable Sleeves

Highlights

- Made from premium aluminum for strength and lightweight durability

- Naturally corrosion-resistant, suitable for indoor and outdoor use

- Easy to crimp with standard tools for quick and secure installations

Description

Our premium aluminum cable sleeves, known for their lightweight design and excellent corrosion resistance, provide a reliable and long-lasting solution for creating secure loops and splices in wire rope assemblies. Ideal for demanding environments, these sleeves offer exceptional performance and durability for various industrial, marine, and construction applications.

Click button to download the cut sheet automatically